Extension Springs

Wire Springs

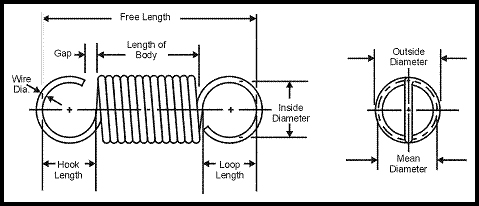

Extension springs are tightly coiled springs designed to resist a tensile, or stretching, force. When pulled outward, the spring will attempt to pull back into its coil. As the spring is extended further, its resistance increases. An extension spring can both absorb and store energy, as well as create resistance to a pulling force. Extension springs often have a loop or hook at the end for mounting the spring. An extension spring is in most cases mounted on other objects that are in motion. When these objects move, the extension spring attempts to bring the objects back to their start position.

An extension spring is wound so that there is an initial tension in the coils that holds the coils against one another and thus tightly together. This initial force (also called initial tension) is the force that must be overcome to set the extension spring in operation, thus it must be pulled so much the coils are no longer touching. All standard extension springs are wound with initial tension. The initial tension is not guaranteed to be uniform for different production runs. If precise initial tension is required, or consistent initial tension, it is possible to make a special extension spring that meets the desired requirements. It is possible to make an extension spring with almost no initial tension and long travel as a result, or a high initial tension and short travel as a result Construction, environment, installation factors and operating conditions all determine how the extension spring should be dimensioned to achieve maximum performance. The force of an extension spring is linear apart from the introductory section, where the initial tension has to be overcome.

Choosing the Right Springs Manufacturer Matters!

Put Us To Work For You!

Design Considerations: Extension Springs

Design Equations

Design equations for extension spring are similar to Compression Springs. The rate is given by:

Where P1 is initial tension. Stress is given by:

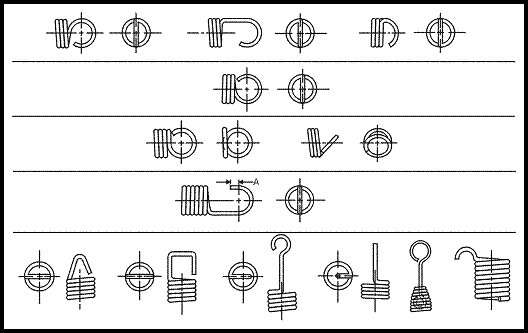

Types of Ends

Extension springs require a method of attachment to other parts in an assembly. A wide variety of ends have been developed and used successfully for many years - for example, threaded inserts, swivel hooks, twist loops, side loops, cross-center loops and extended hooks. Loops are attachment ends that have small gaps, while hooks are loops with a large gap. In fact, the variety of ends is almost unlimited. The most common configurations are those that can be formed during the springmaking operation. Typical types include twist, cross center, side loops and extended hooks. Many of these configurations are made by bending the last coils of an extension spring to form loops. Most special hooks are formed from straight sections of wire on the so-called "tangent ends" of an extension spring body.

Custom Extension Springs