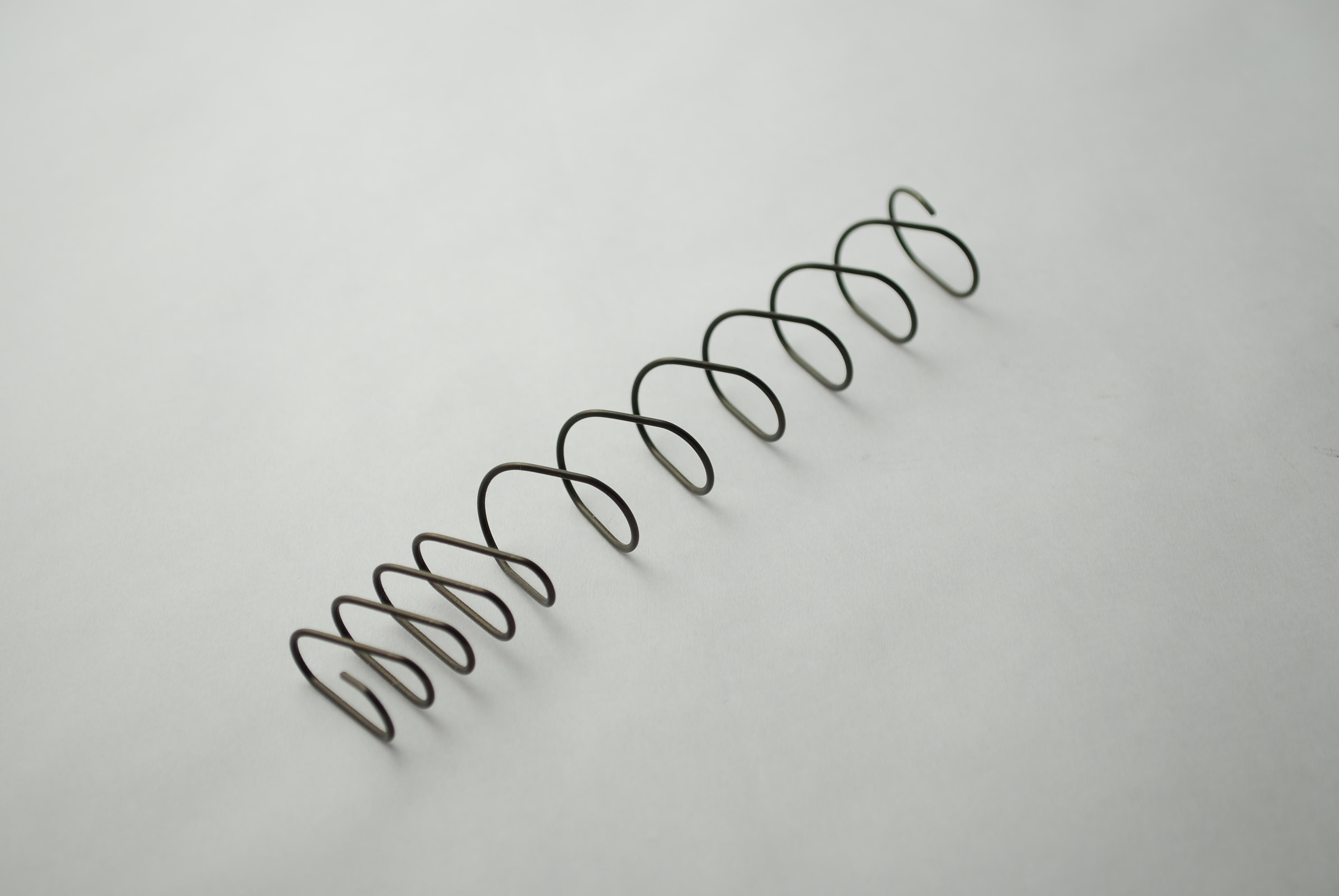

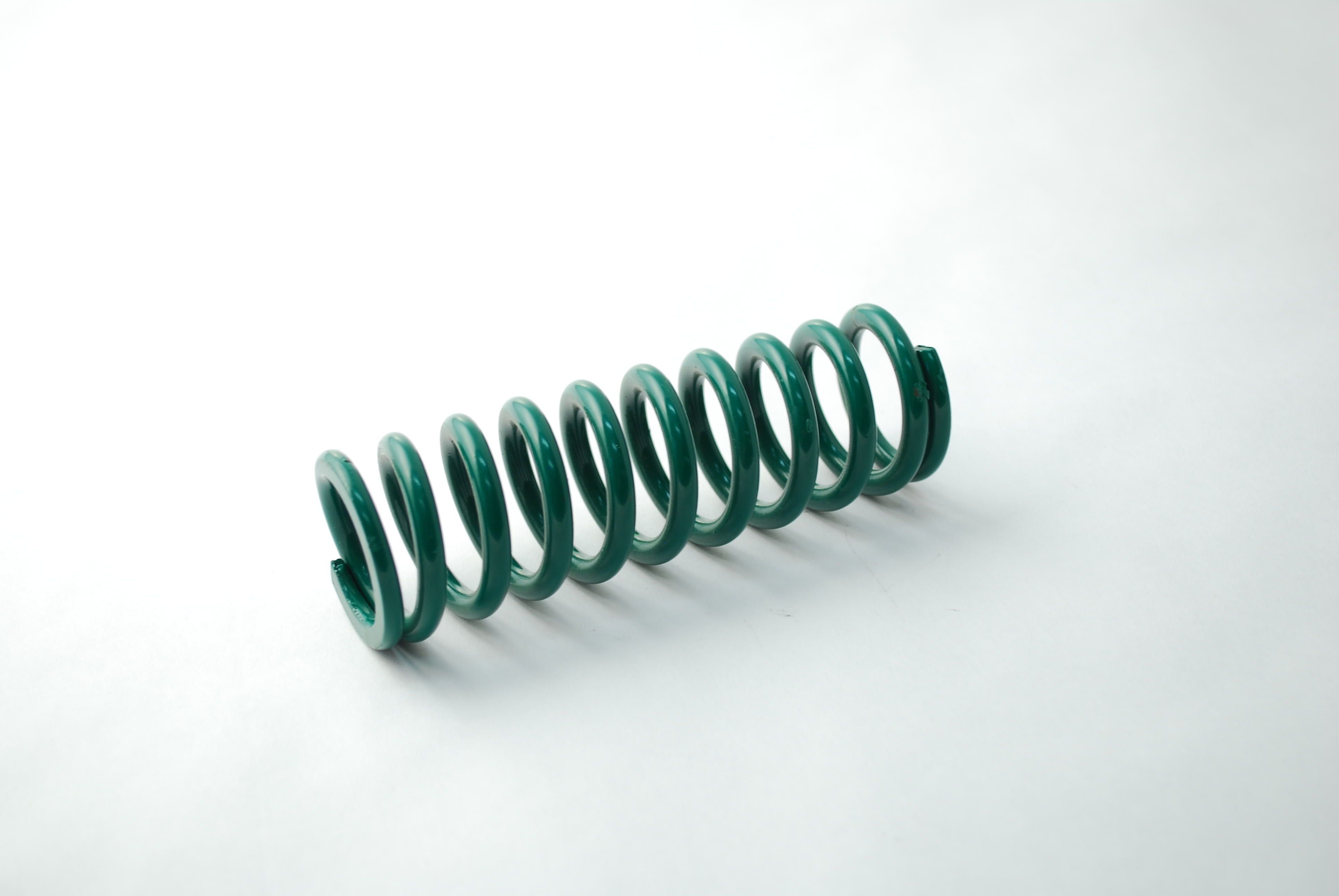

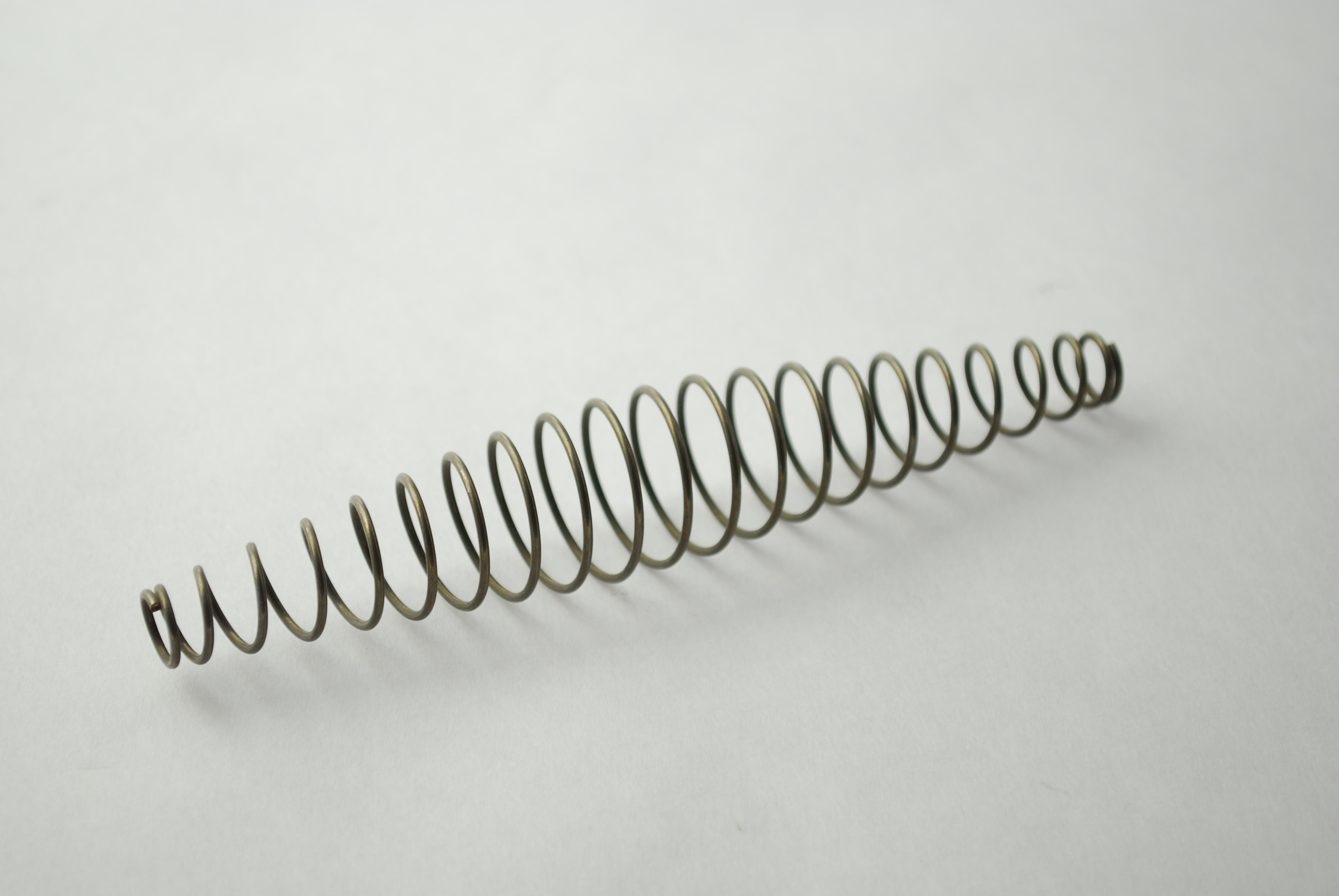

Wire Springs

A torsion spring is a spring that works by torsion or twisting; that is, a flexible elastic object that stores mechanical energy when it is twisted. When it is twisted, it exerts a force (actually torque) in the opposite direction, proportional to the amount (angle) it is twisted. There are two types. A torsion bar is a straight bar of metal or rubber that is subjected to twisting (shear stress) about its axis by torque applied at its ends. A more delicate form used in sensitive instruments, called a torsion fiber consists of a fiber of silk, glass, or quartz under tension, that is twisted about its axis.