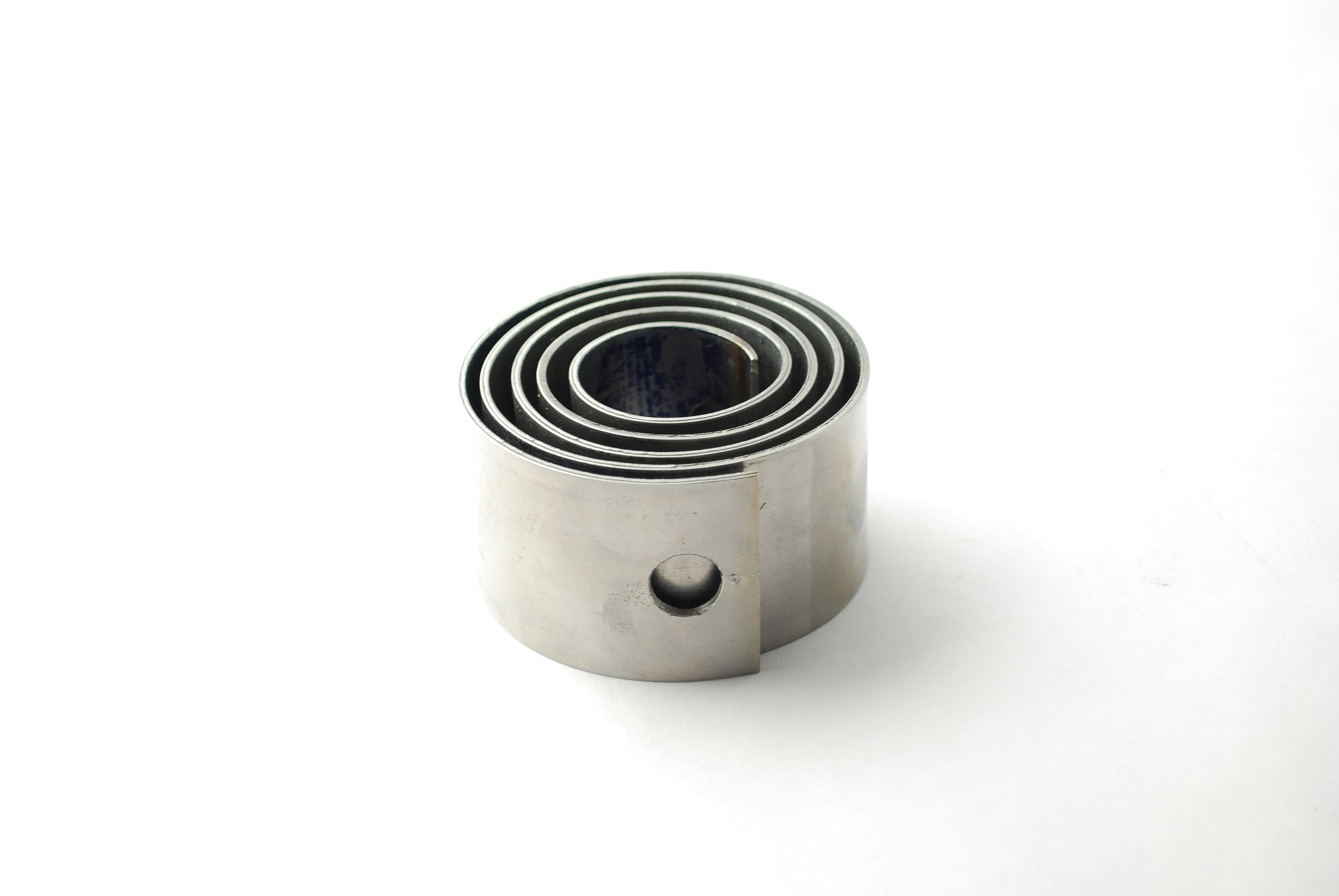

Flat Springs

Fourslide metal stamping is a metal forming process in which flat stock sheet metal, formed from metals such as steel, aluminum, zinc, nickel and titanium, etc., is shaped into predetermined parts in a stamping press. During press operation, the slide, or ram, maintains movement to and from a motionless table called a press bed. The die, a press tool consisting of a specially designed cavity, shapes metal parts from the inserted sheet metal. The upper component of the die connects to the press slide, and the lower component connects to the press bed. A die component called the punch performs the necessary shaping operation by pushing the sheet metal through the die.