Double Torsion Springs

Wire Springs

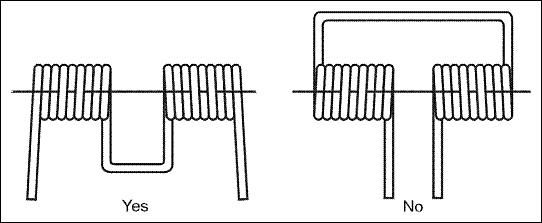

Double-bodied Torsion Springs are designed using the same methods as for single-bodied Torsion Springs. The rate for a double Torsion Spring is equal to the sum of the rates for each component. For the same wire diameter, coil diameter and wire length, double Torsion Springs have rates four times those of single-bodied types. Double Torsion Springs should be designed so they are coiled out from the center rather than in from the ends.

Double Torsion Springs are stressed in bending. Rectangular wire is more efficient in bending than round wire, but due to the premium cost of rectangular wire, round wire is preferred. If possible, a Torsion Spring should always be loaded in a direction that causes its body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring is loaded in a direction which increases body diameter. Unless there are unfavorable residual stresses in the end bends, springmakers normally heat-treat these springs at a low temperature to stabilize the end positions rather than to fully stress relieve them. If the direction of loading tends to increase body diameter, the springmaker should be advised to stress relieve the springs.

Choosing the Right Springs Manufacturer Matters!

Put Us To Work For You!

Design Considerations: Double Torsion Springs

Double-bodied Torsion Springs are designed using the same methods as for single-bodied Torsion Springs. The rate for a double-bodied Torsion Spring is equal to the sum of the rates for each component. For the same wire diameter, coil diameter and wire length, double-bodied Torsion Springs have rates four times those of single-bodied types. Double-bodied Torsion Springs should be designed so they are coiled out from the center rather than in from the ends.

Spring Rate

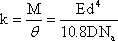

Spring rate for helical round wire Torsion Springs is given by:

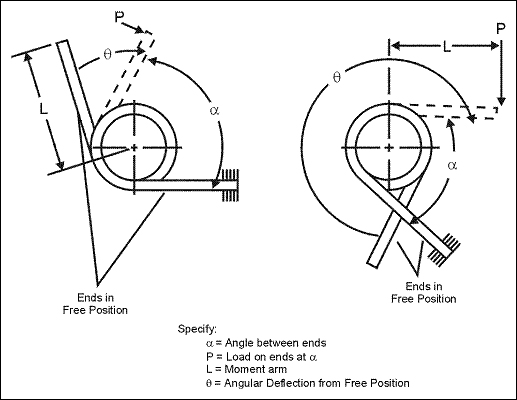

The 10.8 factor is greater than the theoretical factor of 10.2 to allow for friction between adjacent spring coils and between the spring body and the arbor. This factor is based on experience and has been found to be satisfactory. Loads for Torsion Springs should be specified at a fixed angular position and not at a fixed deflection from the free position. Presently, there is no standard way to test loads for Torsion Springs.

Custom Double Torsion Springs