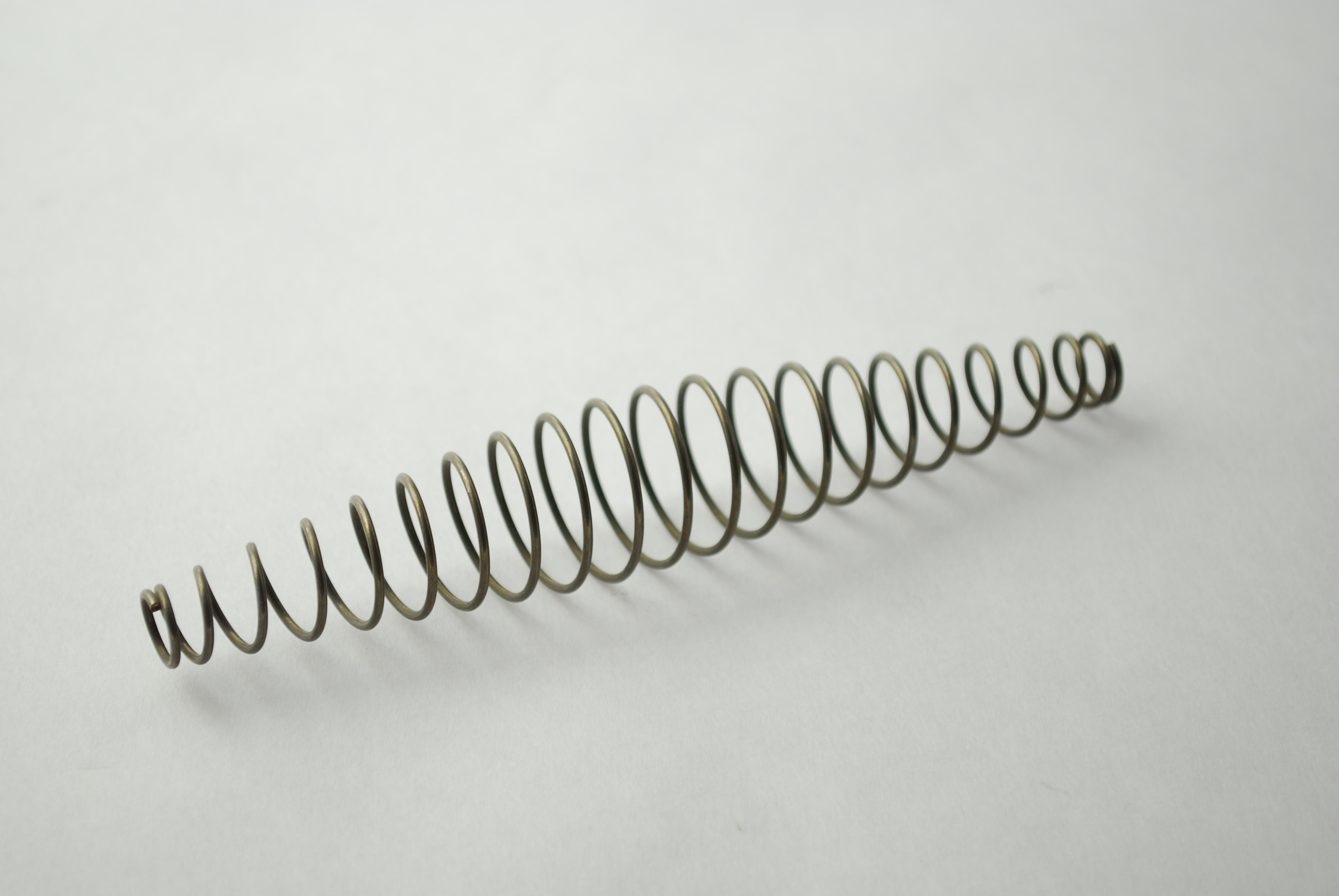

Barrel Springs

Wire Springs

Barrel Springs are used in applications requiring a low solid height, increased lateral stability or resistance to surging. Hourglass springs can be designed so that each coil nests wholly or partly into an adjacent coil. Solid height can be as low as one wire diameter. Rate for barrel springs usually increases with deflection because the number of active coils decreases progressively as the spring approaches solid. By varying the pitch, barrel springs can be designed to have a uniform rate. Rate for barrel springs is calculated, as indicated previously, by considering the spring as many springs in series.

Barrel Springs are used to resist applied compression forces or to store energy in the push mode. They have the most common spring configuration and are found in many applications such as automotive, aerospace and consumer goods. While the most prevalent form of a Compression Spring is a straight barre spring made from round wire, many other forms are produced. Hourglass forms are available, with or without variable spacing between coils. Such configurations are used to reduce solid height, buckling and surging, or to produce nonlinear load deflection characteristics.

Choosing the Right Springs Manufacturer Matters!

Put Us To Work For You!

Custom Barrel Springs